Talaan ng mga Nilalaman

I-toggleControl Cabinet Upgrades

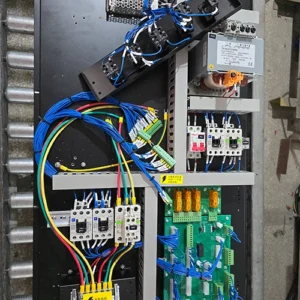

In the fast-paced world of industrial operations, every detail counts. One critical component that often goes unnoticed by many is the control cabinet. Over time, these control cabinets can become outdated, leading to inefficiencies and potential safety hazards. Embracing kontrolin ang mga pag-upgrade ng cabinet can not only improve operational efficiency but also enhance safety in industrial environments.

The Importance of Control Cabinets

Control cabinets serve as the nerve center for electrical control systems. They house crucial components like switches, relays, and controllers. An outdated control cabinet can lead to several issues, such as increased energy consumption, slower response times, and even equipment failures. For instance, a manufacturing plant that relies on a decades-old control cabinet might experience frequent downtime simply because the components within it are no longer reliable.

Efficiency Through Modernization

One of the most compelling advantages of control cabinet upgrades is enhanced efficiency. Modern control cabinets incorporate advanced technologies that streamline processes. For example, consider a plastic extrusion facility that upgraded its control cabinet to include programmable logic controllers (PLCs) with real-time monitoring. Prior to the upgrade, machine operators relied on manual checks and balances, often leading to delays. Post-upgrade, operators can monitor the production line in real time, adjusting parameters on-the-go. This shift not only speeds up production but also minimizes waste and reworks, directly impacting the bottom line.

Moreover, newer control cabinets are designed with energy efficiency in mind. By integrating smart power distribution systems, companies can significantly reduce their energy costs. A food processing plant that embraced **control cabinet upgrades** could cut its energy consumption by 20%, resulting in substantial savings that can be reinvested into the business.

Enhanced Safety Measures

Safety is another crucial aspect that control cabinet upgrades address. Outdated cabinets often lack modern safety features, exposing workers to unnecessary risks. For example, an old cabinet may have inadequate ventilation, leading to overheating and potential fire hazards. Upgrading to a newer model with enhanced cooling systems reduces this risk significantly.

Furthermore, a new control cabinet can integrate advanced alarm systems and sensors that detect malfunctions. A manufacturing unit that upgraded its control cabinet to include these safety features reported a 30% decrease in workplace accidents related to electrical failures. With these systems in place, operators can be alerted to any irregularities well before they escalate into serious issues.

Applicability Across Industries

The benefits of control cabinet upgrades extend across various sectors, including manufacturing, energy, and even transportation. In the oil and gas industry, for example, control cabinets manage critical operations such as drilling processes and transmission controls. By upgrading to more reliable and efficient systems, operators can ensure smoother operations, reduce downtime, and protect their equipment from costly failures.

Similarly, in the renewable energy sector, control cabinets play a vital role in managing the performance of solar panels and wind turbines. Upgrading these cabinets can lead to better monitoring and regulation of energy outputs, optimizing the overall efficiency of these critical renewable sources.

Conclusion: A Switch to Modernization

Investing in control cabinet upgrades is not merely a maintenance task; it’s a strategic move toward enhanced efficiency and safety. By modernizing these essential components, businesses can improve their operational reliability while also safeguarding their employees. As companies continue to seek ways to boost productivity and ensure workplace safety, control cabinet upgrades present a clear path forward.

In the competitive industrial landscape, where efficiency and safety are paramount, the decision to upgrade may very well be the difference between a thriving operation and an outdated one. Therefore, taking proactive steps to upgrade control cabinets should be at the forefront of industry leaders’ agendas. With the right upgrades, the future looks not only safer but much brighter.